Challenges

A manufacturer of hydraulic components and systems needed to make some modifications to a 10HP wheeled vehicle to meet their customer’s goals:

- Speed Optimization: The wheeled vehicle’s propulsion system and driving interface fell short of the required 6 mph operating speed, limiting its performance and utility.

- Maneuverability Enhancement: Under certain conditions, the vehicle would enter an uncontrolled circular motion, causing loss of forward momentum and excessive spinning. This “death spiral” significantly impacted operational effectiveness.

- Cost Reduction: The existing design incorporated an unnecessarily complex mechanical and hydraulic system, driving up both production and maintenance costs while reducing overall efficiency.

Solution

Through collaboration between QP and the hydraulic manufacturer, the wheeled vehicle’s performance was transformed by reimagining its control system. The original design relied on a twin pump-motor configuration with mechanical handlebar controls and a separate throttle lever. The previous control limited both speed and maneuverability.

Our comprehensive redesign included:

- An optimized engine hydraulic system

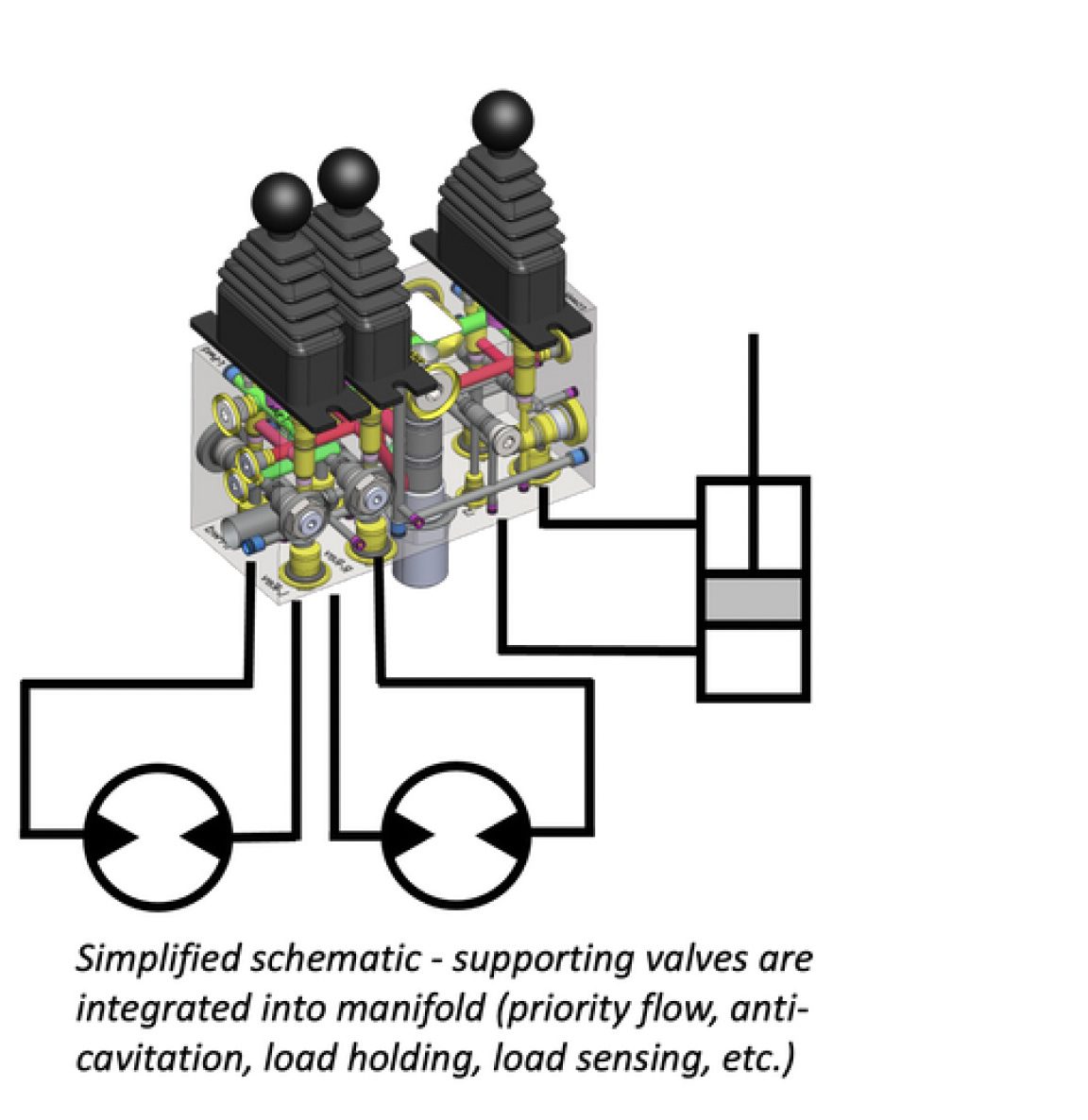

- QP’s advanced hydraulic manifold

- Enhanced operator interface

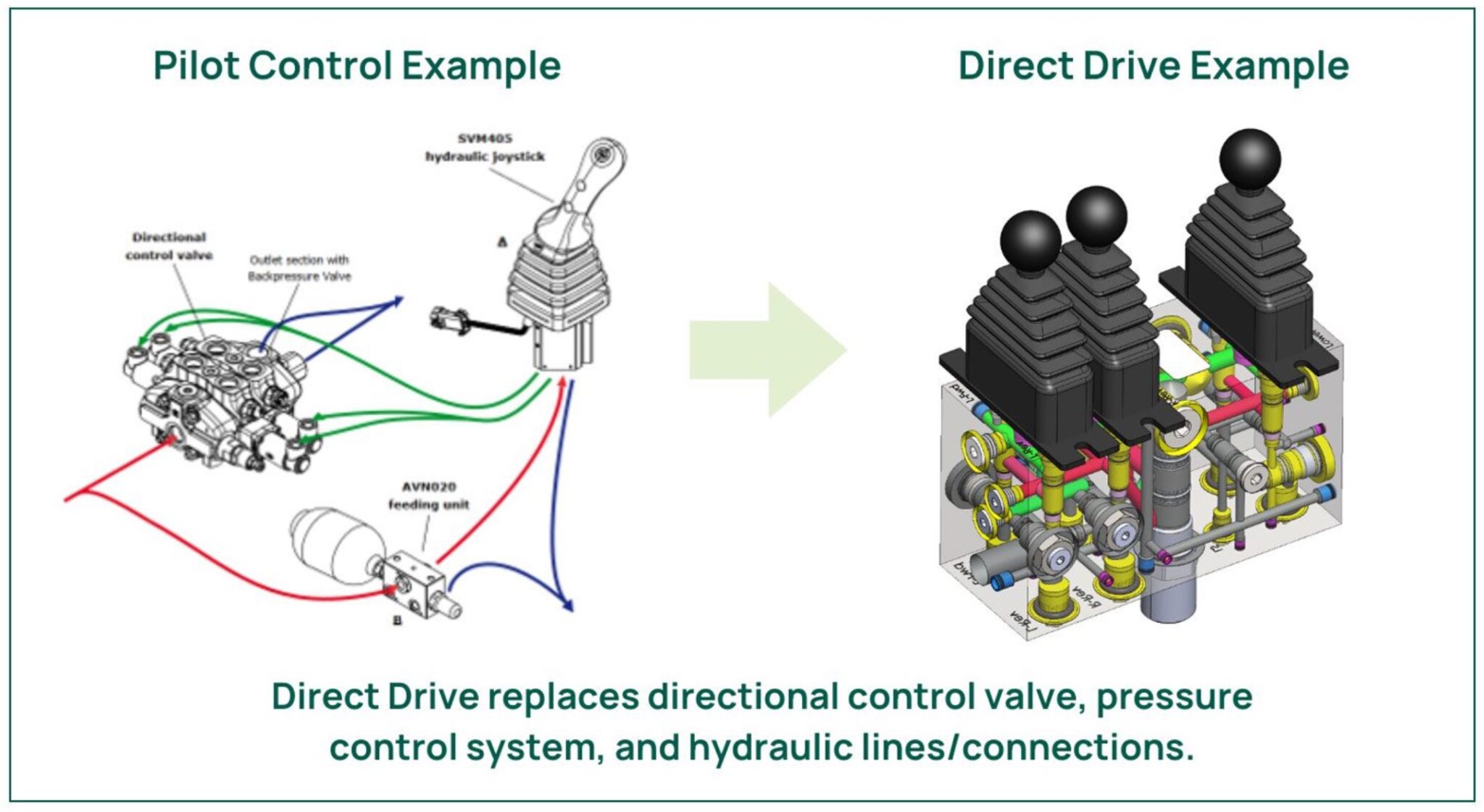

- State-of-the-art Direct Drive hydraulic joystick

Superior Speed AND Controllability

The integration of QP’s Direct Drive joystick technology created a direct fluid connection between the pump and actuators (motors,cylinders), delivering:

- Enhanced top speed exceeding 7 mph

- Precise speed control

- Superior skid-steer maneuverability

- Simplified operation through intuitive controls

Better Pricing

The wheeled vehicle’s streamlined redesign eliminated unnecessary complexity, resulting in a substantial cost reduction. The optimizations delivered substantial cost savings while enhancing reliability and performance, providing the manufacturer’s customer with a more competitive and profitable product solution.

Key Advantages of QP’s Direct Drive Joysticks:

- Direct replacement for traditional directional control valves

- Familiar, intuitive control interface

- Eliminates need for cast sections

- Reduces dependency on cartridge and D03 control valves

- Streamlines hydraulic systems

Conclusion

The collaborative solution between QP and the hydraulic manufacturer exceeded their customers’ expectations, revolutionizing wheeled vehicle performance and control dynamics. QP’s Direct Drive Joystick technology delivered intuitive operation comparable to premium off-highway equipment, while significantly simplifying system architecture.