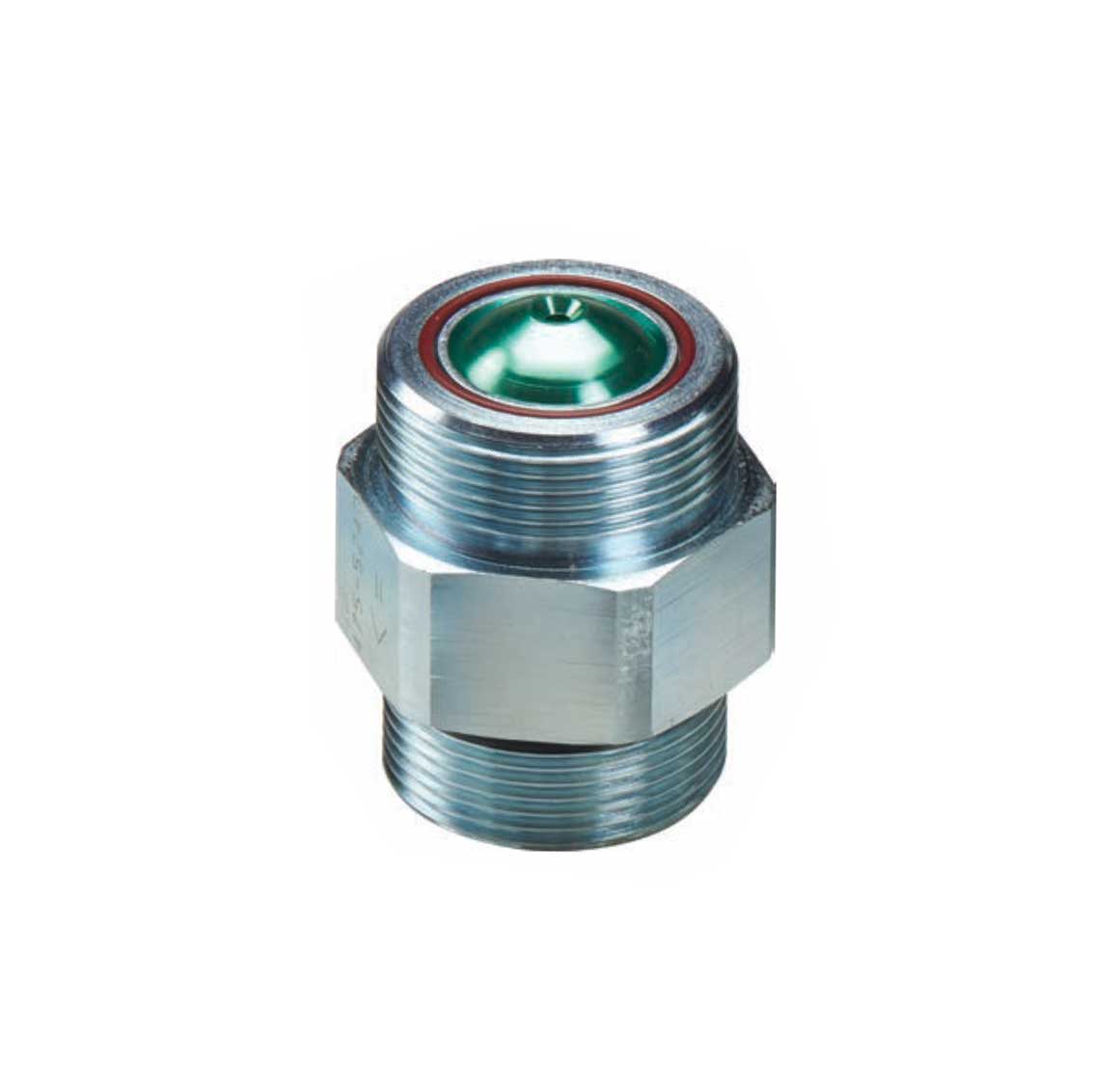

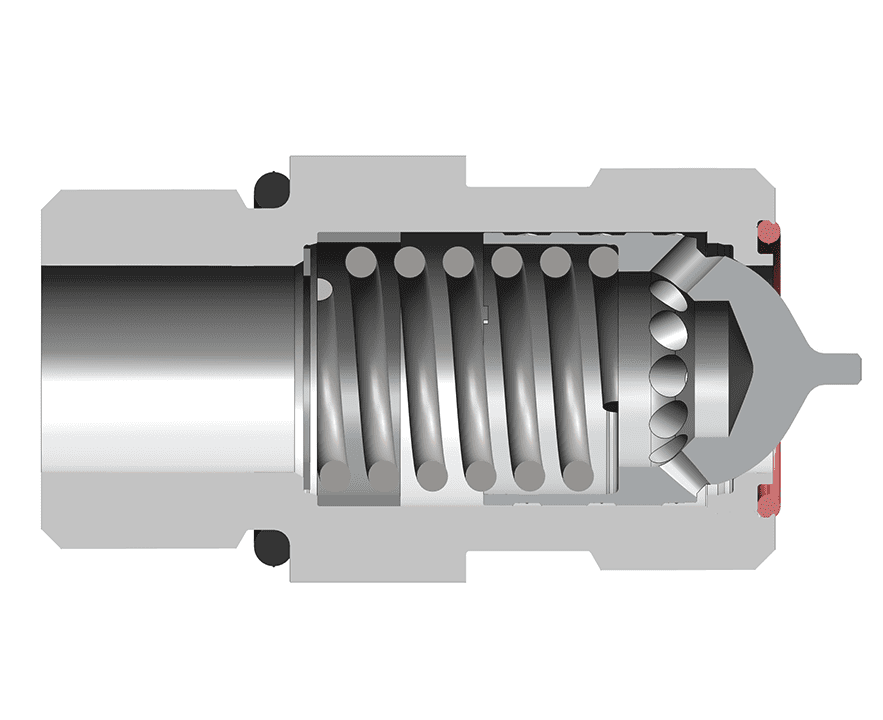

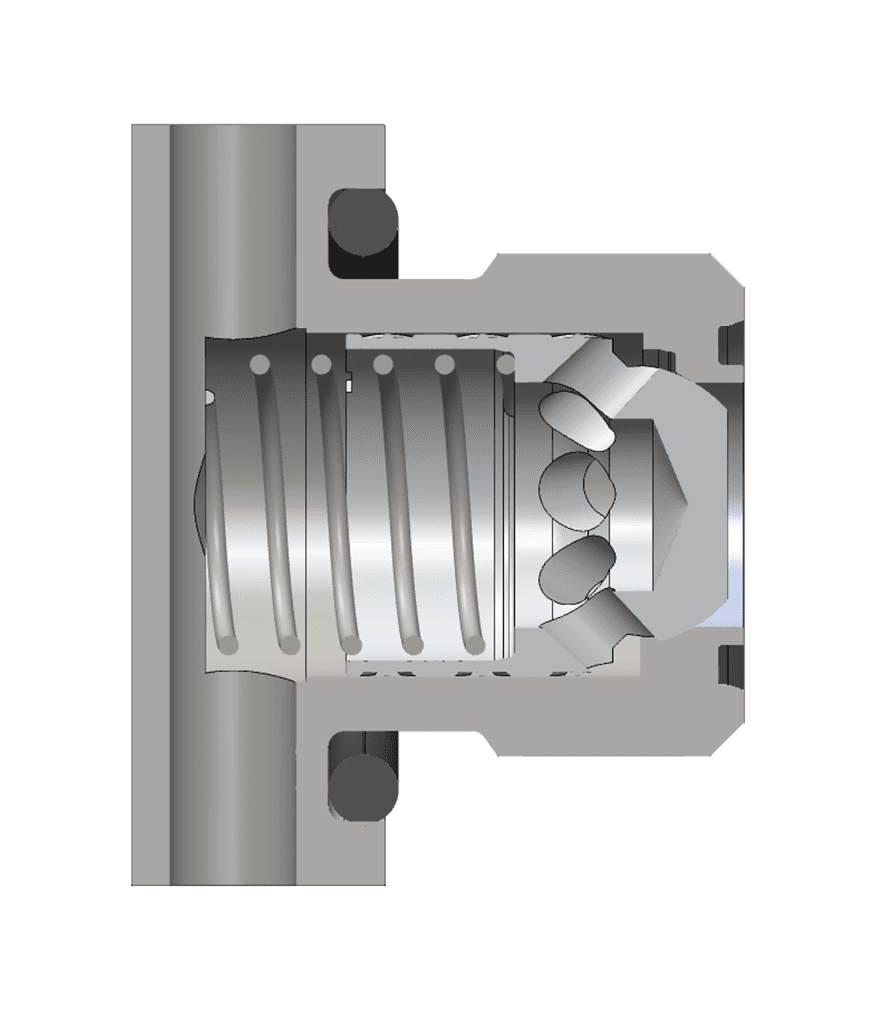

Low-Mass Check Valves

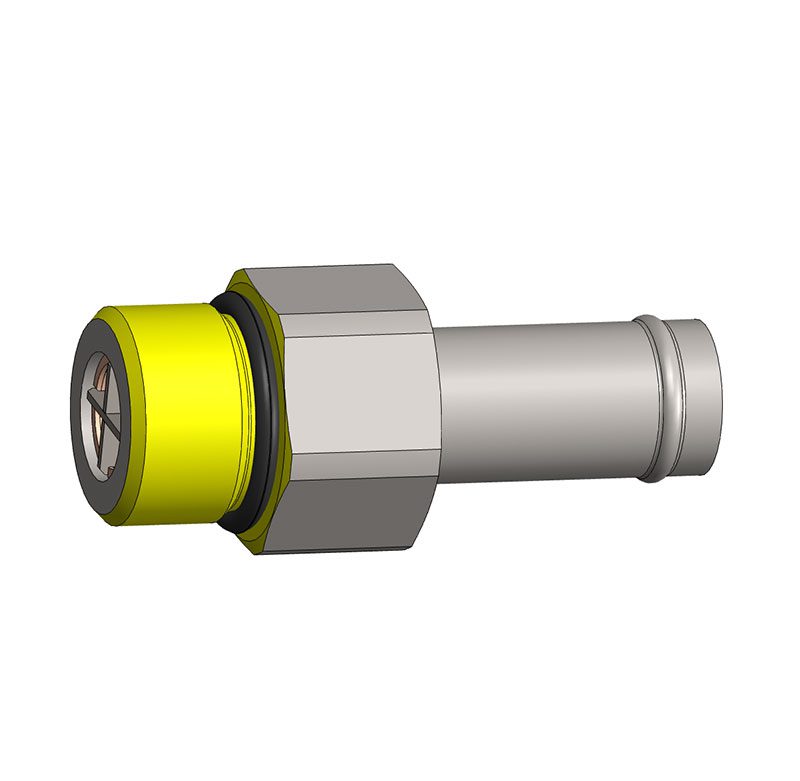

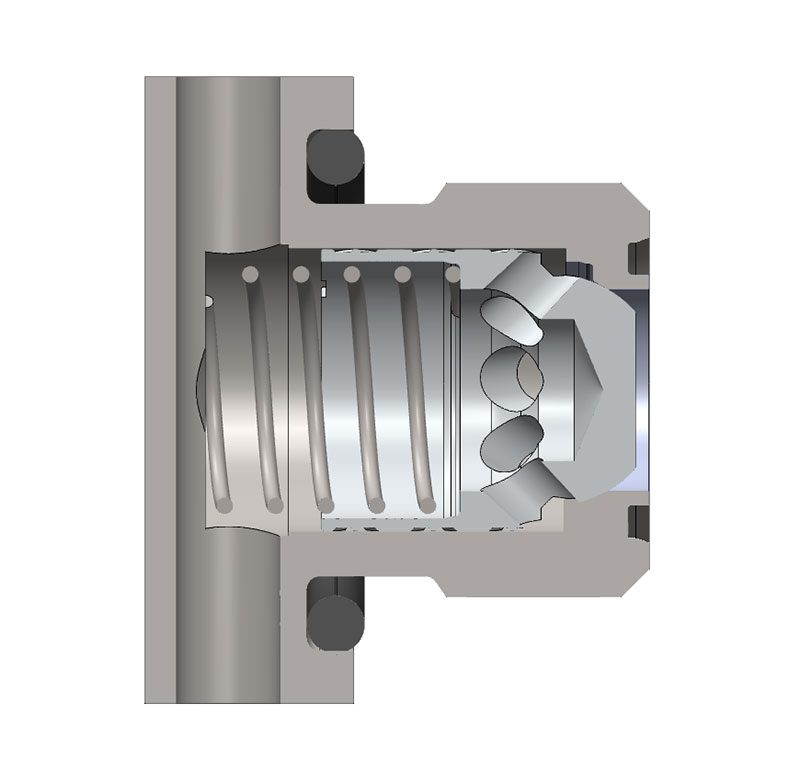

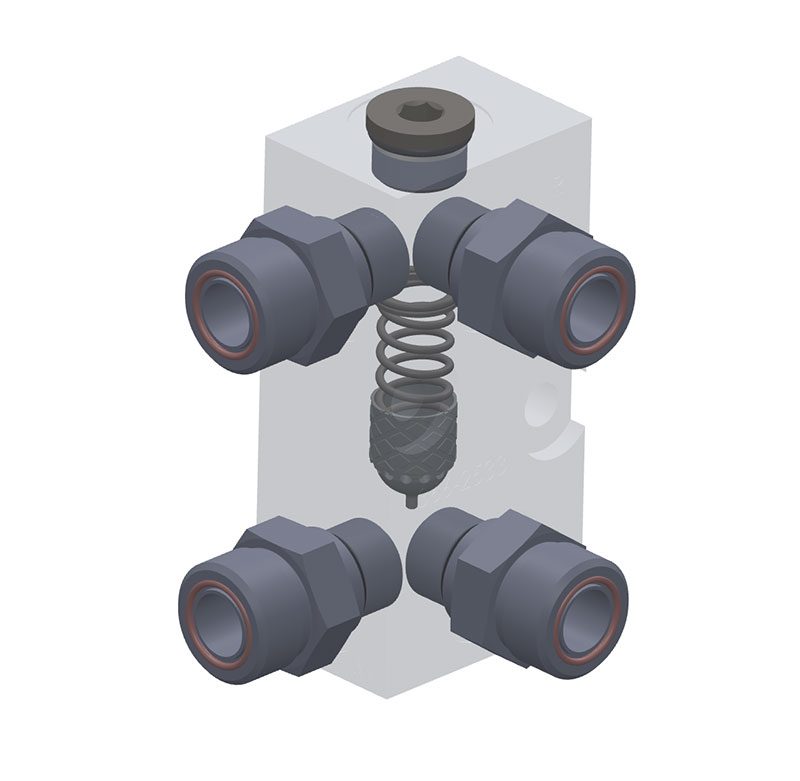

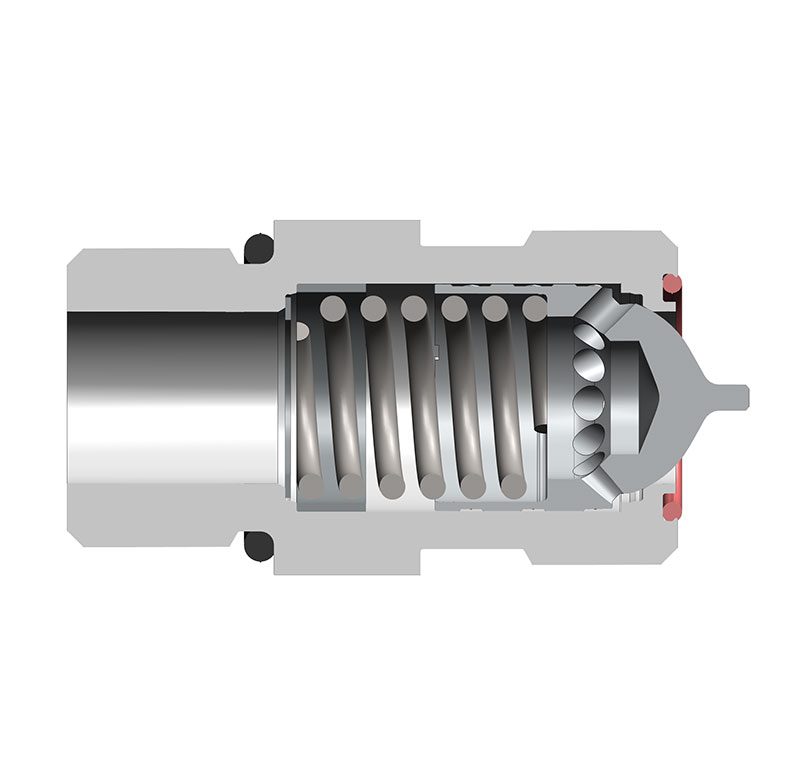

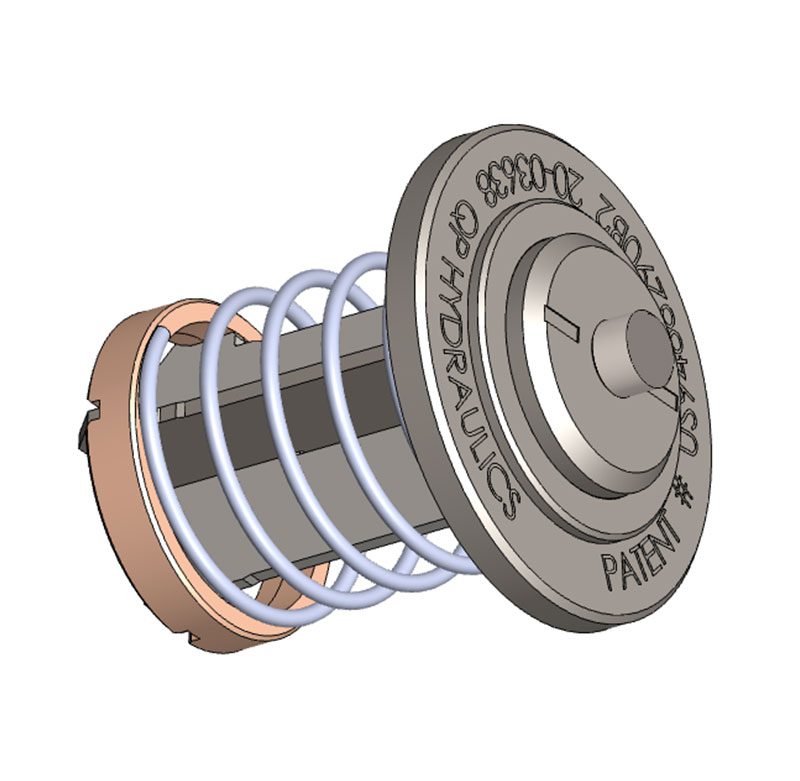

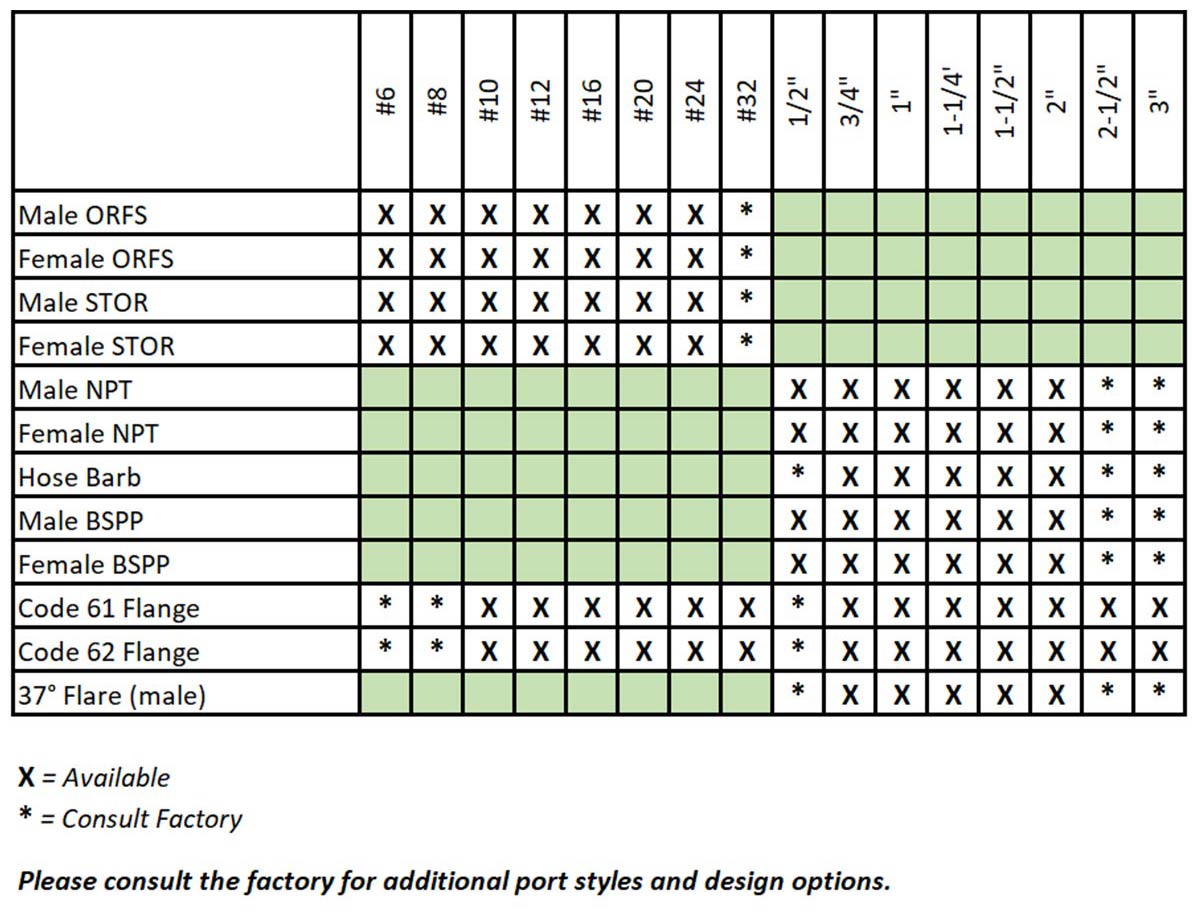

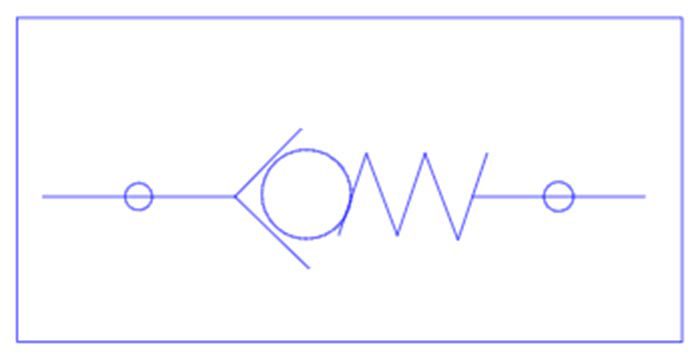

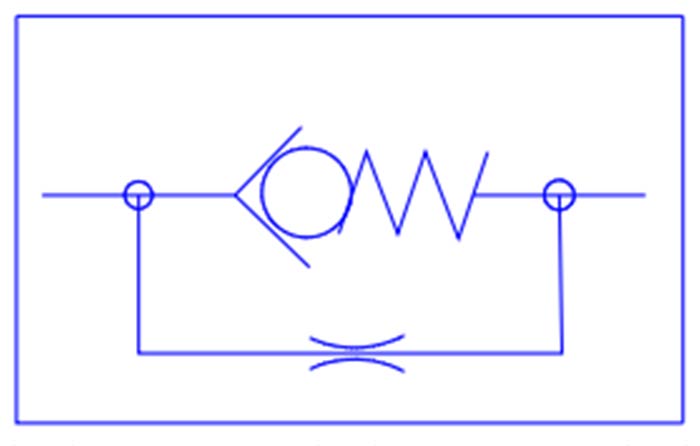

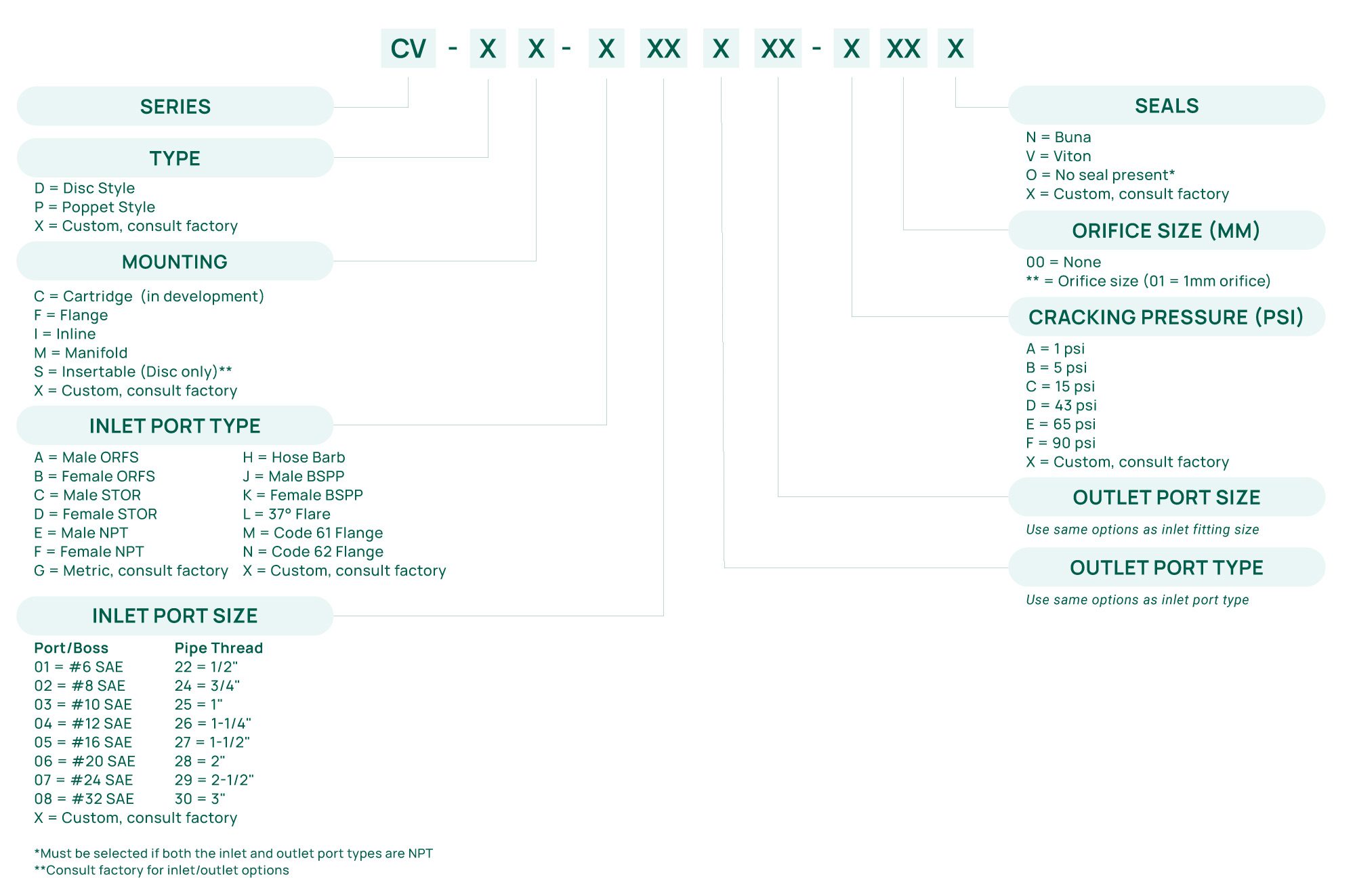

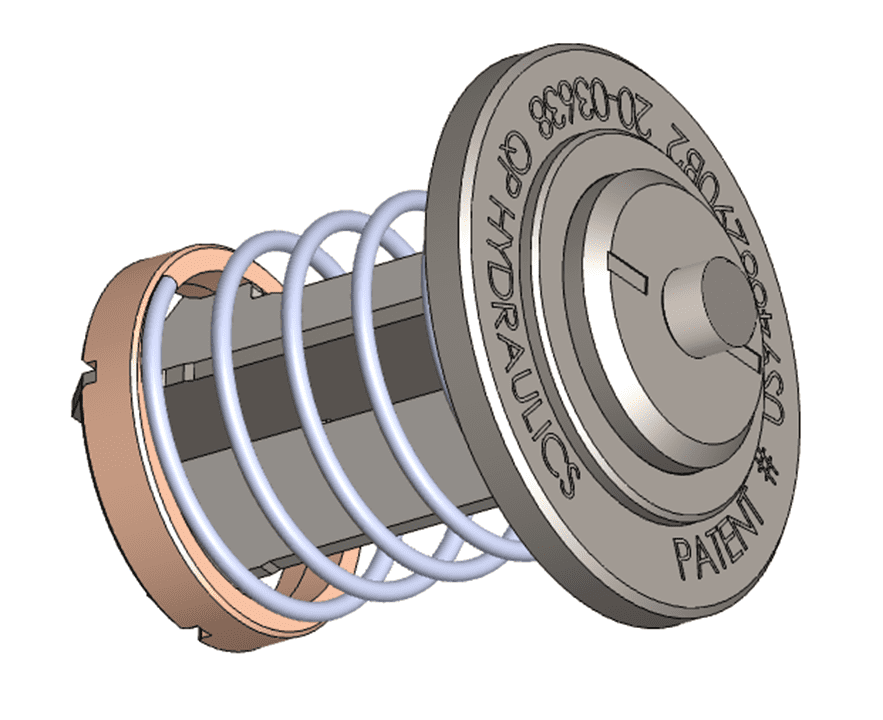

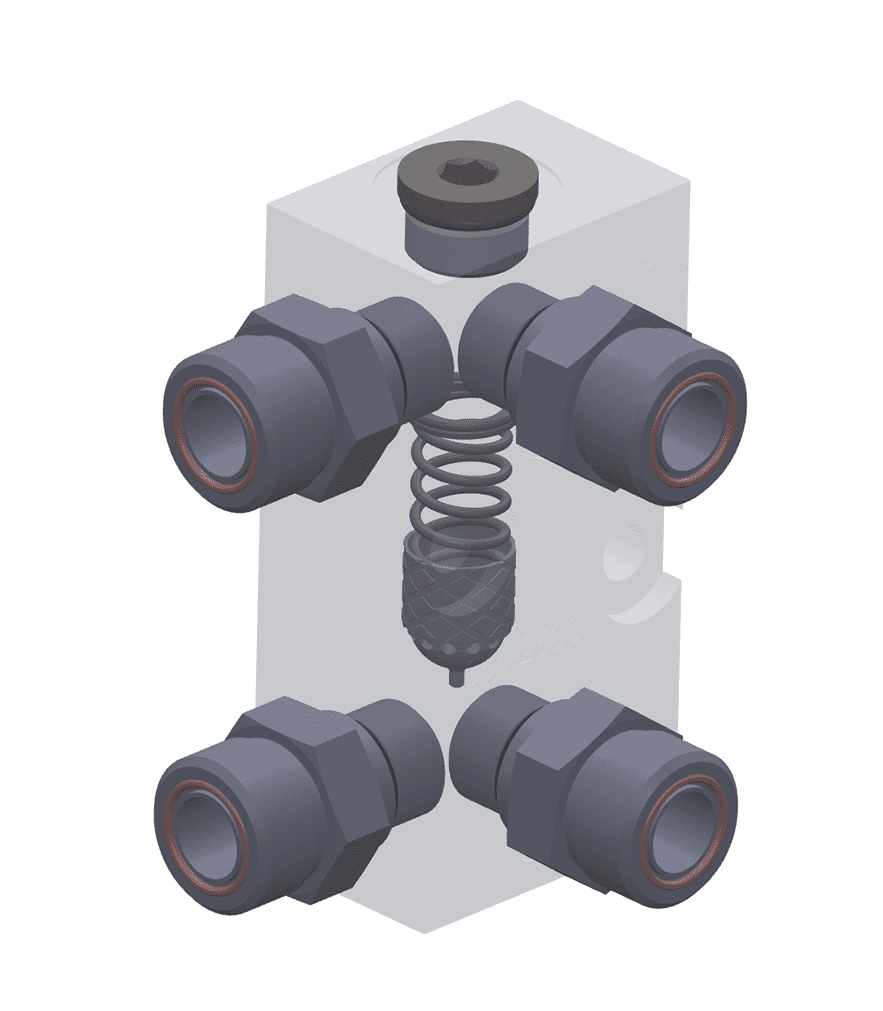

Our innovative line of low-mass check valves provides low-shock solutions for a variety of system instability challenges. Our CV-D (disc type) and CV-P (poppet type) can be configured to solve many “traditional” system issues.

KEY FEATURES/BENEFITS:

- Solve system instability problems

- Low-mass = low-shock

- Solve system “noise” problems

- Both high- and low-pressure solutions

- Standard fittings and connections

- Highly customizable

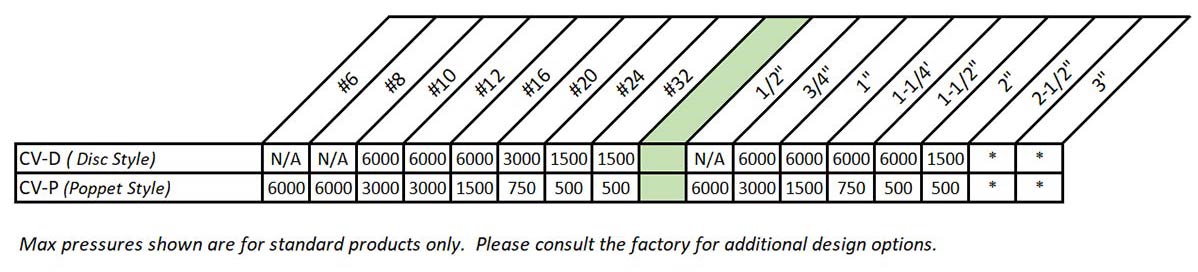

| Max Operating Pressure: | 6000 PSI (414 BAR)* |

| Max Flow: | Consult factory |

| Cracking Pressure: | 1,5,15,43,65,90 PSI (STD) |

| Leakage: | 1cc/min @ 2500 PSI |

| Temperature: | -40 ~ 200°F (Buna seals) |

| Fluid Type: | Mineral Oil ISO, HM & HV (10W recommended) |

*Please review pressure chart for max pressures by type/size